Our services

Provider

Location

- Connections for the high-tech equipment

- Installation of the lab lighting

- Wiring of the emergency lighting as well as the smoke and gas detectors

Lonza AG and its partners expanded the Ibex Solutions biopark in Visp (Valais) in 2020. Around CHF 1 billion was invested in the massive project. The new lab building will, for example, help pharmaceutical companies to produce new, lifesaving medications even more quickly. Key quality controls will also be carried out in future for the US biotech company Moderna, which successfully developed a COVID-19 vaccine.

«The 60 or so people who work in the building are happy because they have never worked in such a modern lab before.»

- Completion

2020

- Construction type

Electrical installations

- Contruction style

New construction

- Branch

Pharmaceutical industry

- Carried work

High and low voltage systems, installation of emergency lighting, smoke and gas detectors

- Project manager

Stefan Luggen, Werner Electro AG

- Builder

Lonza Group AG

- Construction cost

CHF 1 billion

- Installation cost

CHF 4.5 million

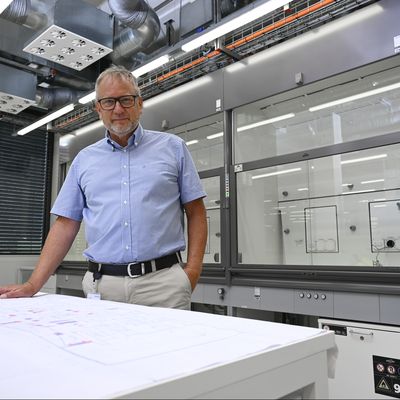

The project to construct the new building, which is 30 metres high, 40 metres wide and 80 metres long and has 15,000 square metres of space, commenced in May 2019. “That made the schedule quite tight for everyone involved,” says Felix Burger, who had overall responsibility for the lab project at Lonza. However, the biggest challenge was organising everything to allow everyone to work together seamlessly. “At peak times, there were around 280 people working in the new lab building at the same time,” says Felix Burger. One of these professionals was Stefan Luggen. He is the managing director of Werner Electro AG, which is part of BKW Building Solutions and a specialist in electrical installations. Among other things, Luggen’s team laid the electrical cables and prepared the connections for the high-tech equipment. “We laid around 180 kilometres of cable and installed 1,700 network connections,” he says. Not an easy job when it involves highly complex lab equipment where measurements have to be carried out and data transmitted at each lab space. To ensure that everything functioned seamlessly, the entire electrical installation had to be perfect. Luggen and his team also took care of the lighting. In the labs, the researchers need light that is bright, but not too harsh. Werner Electro AG also took care of wiring the emergency lighting as well as the smoke and gas detectors. All important factors when it comes to safety. A total of CHF 4.5 million in electrical materials was installed, says Stefan Luggen. “From the start of the project in January to the end in August, that’s CHF 600,000 per month.”

What distinguished this project from all of the others he has worked on? “Before the building technical systems were commissioned, we had to measure and commission each individual piece of equipment. We had never done that before.” Luggen therefore had to provide five people with special training – on the job. And he had to hire temporary staff to do so. “At peak times, we needed up to 80 people, all of whom had to be very well qualified.” The biopark design was highly appealing to the clients. “The building shell can be expanded in a flexible and modular manner, depending on the technology. As a result, we can respond to customer needs more quickly,” says Renzo Cicillini, the site manager of Lonza Visp. This is important, especially in a case like the coronavirus. As Stefan Luggen notes: “The chemical industry and Lonza are seeing extraordinary growth. We are active in the region and simply cannot let such opportunities pass us by. That’s why it was very important for us to show that we can complete this kind of project.”